Product Range

| TYPES PRODUCED | SIZE RANGE | STANDARDS FOLLOWED |

|---|---|---|

| Seamless Drawn | OD 1 mm to 170 mm |

IS 738, EN 754, IS 4993, ASTM / ASME B 483, ASTM B210, IEC 60153, JSS 53000, BS 4L - 100, ASTM B221 |

| Port hole Extruded Drawn | Thickness 0.1 mm to 10 mm | |

| Rods, Tubes, Profile & Tubes in Coil Form | Rod up to Ø 35 mm |

Alloy Range

| ALLOYS | ||||||

|---|---|---|---|---|---|---|

| 1-Series | 2-Series | 3-Series | 5-Series | 6-Series | 7-Series | Other Alloys |

| 1050 | 2014 | 3003 | 5049 | 6005 | 7075 | 5XXX ( АMg6 / АМг6 ) |

| 1070 | 2017 | 3100 | 5052 | 6060 | 7049 | V65 |

| 1100 | 2024 | 3103 | 5056 | 6061 | - | - |

| - | 2219 | - | 5083 | 6063 | - | - |

| - | - | - | 5086 | 6082 | - | - |

| - | - | - | - | 6351 | - | - |

Defence Customers

Advantages

These extruded and drawn products fulfill the requirements of Good Surface Finish; have

very close dimensional tolerances and added mechanical properties which are used

for:

Very close Dimensional

Tolerances :- +/- 0.02 mm

Very Good surface finish :–

Ra 0.4 µ

Added Mechanical / Physical

Properties

Accurate Straightness :–

1:4000 mm

Very small (from 1 mm

diameter) very thin (from 0.2 mm) section is possible

Non-heat treatable, alloy

can be given in work Hardened Condition. Which results in added mechanical properties

Very precise Quality and

Eccentricity

Special Shapes with High

Accuracy in Dimension

Telescopic Profile with

close dimension is possible

Product Quality supported

by own state-of-the-art Quality Assurance Laboratory having all modern testing equipment

Special process like

precision cutting in small pieces (Tolerance of ± 0.2 mm)

Bending, Flaring, Punching,

Hard Anodizing and color Anodizing can also be carried out on request

Supply to Defence / Government PSU

Telescopic Tubes

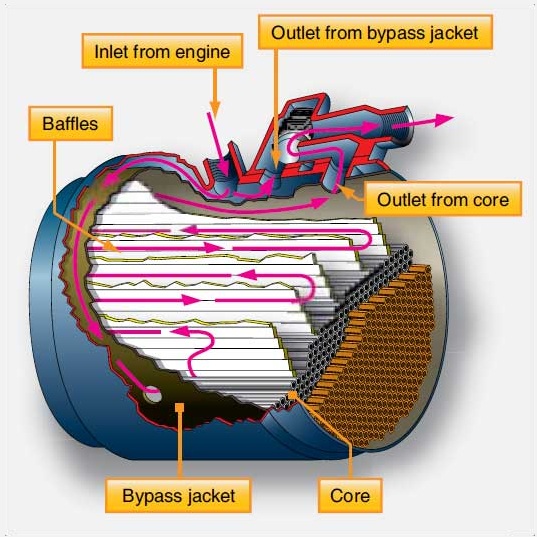

Cryogenic Fuel

Supply Tubes and Heat Pipes

Satellite Waveguides

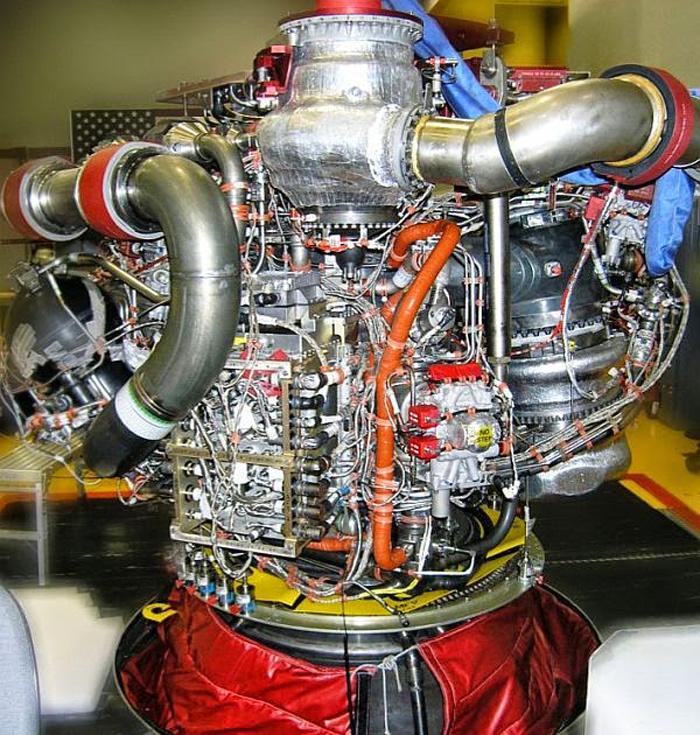

Tubes for Missile

Applications

Tubes for Akash

Missile Project

Fuel Supply Tubes for

Amphibian Tanks

Tubes for Guns, Shells

and Fuse

I/O Connector &

Fibre optic Backshell