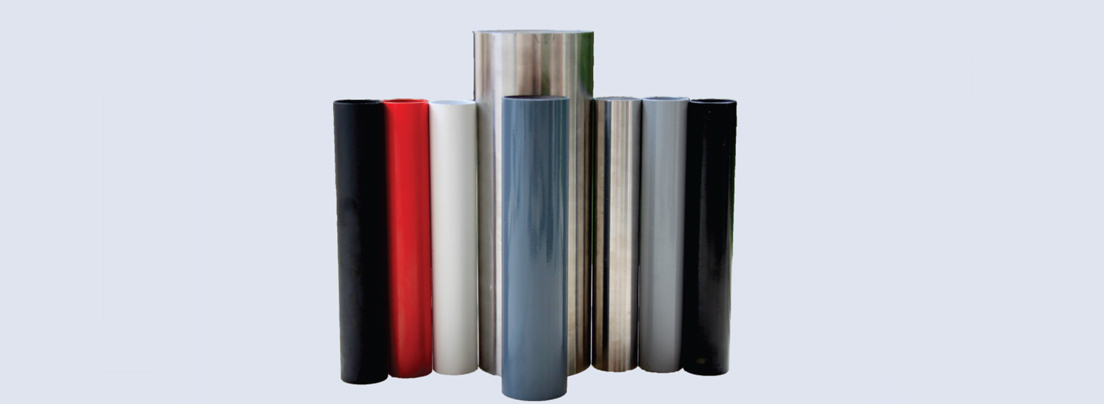

Cold Drawn Aluminium Cheese Tubes

| Sr. No | Dimensions | Weight | ||

|---|---|---|---|---|

| ID | Thickness | Length | (+/- 5 gms) | |

| 1 | 35 | 1.5 | 218 / 230 | 101 / 107 |

| 2 | 35 | 2 | 218 / 230 | 137 / 145 |

| 3 | 35 | 2.5 | 218 / 230 | 173 / 183 |

| 4 | 37 | 1.5 | 218 / 230 | 107 / 113 |

| 5 | 32 | 1.5 | 218 / 230 | 93 / 98 |

*Tube Alloy: 6082

Extruded Aluminium Cheese Tubes

| Sr. No | Dimensions | Weight | ||

|---|---|---|---|---|

| ID | Thickness | Length | (+/- 5 gms) | |

| 1 | 40 | 2.5 | 218 / 230 | 197 / 208 |

| 2 | 35 | 2 | 218 / 230 | 137 / 145 |

| 3 | 35 | 2.5 | 218 / 230 | 173 / 183 |

*Tube Alloy: 6082

Tensile Strength for all the above sizes are 295+ MPa.

Any other sizes required by the customer will be available on request.

Advantages of Cold Drawn tubes over Extruded tubes

Drawn Tube Dimension Tolerances are precise

compared to Extruded Tubes

Better Straightness

Better Ovality

Better Mechanical Properties

Because of the precise dimensions of the

Tubes, the Doff quality will be better which will ultimately create the better weaving quality without any

yarn breakage

We Have Specially Developed some new products

Aluminium Cheese tubes with Adapter on both

the sides

Aluminium Cheese Tubes with 35 mm ID - Tubes

with Grooving in a Two different Models.

We Have Developed Lightest ever

Aluminium Cheese Tubes of 100 Grams

Product Features

High Tensile

Light Weight

Tubes with Precisely Controlled Dimensions

Tubes with length as per customer

requirement

Perfect Roundness and Straightness

Plain and with Anodized Tubes as per

customer requirement

Precise Chamfering with the 90 Degree Right

angle cutting

Advantages

Lowest cost per cycle

Better fitment due to Precise Dimensions

Save Electricity and Maintenance cost

because of the light weight of the Tubes

Productivity increase because of the Light

weight of the Tubes

Better weaving quality due to perfect tube

Roundness

The Salvage value of the tubes shall be

more than 50% of the initial investment cost